Wave Springs

|

Description:

ITK® a renowned name in manufacturing sealing products and component parts have been emphasizing on the production of Wave Springs, Wave Washer and Retaining Ring. Our International technical expertise and experience has its advantage for low cost and high quality Wave springs. ITK® has the facility to supply several series of Wave springs like Single turn, Crest to Crest Wave Spring, Chest to Chest Wave Spring and Nested Wave Springs which are widely used in machinery and equipment industry, Chemical Industry and electrical industry. The overall length and operating height of wave springs are significantly less than that of standard compression springs, thus they will reduce the size of an assembly by as much as 50%. This also reduces the part weight and raw material cost of every spring produced.

|

||

|

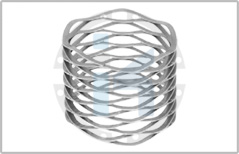

Nested Wave Springs: Nested Wave Springs are pre stacked in parallel from one continuous filament of flat wire. The elasticity is proportional to the number of turns. They can exert tremendous forces yet maintain the precision of a circular grain wave spring. In many applications, Nested Wave Springs can replace Belleville Springs, particularly in cases where a high but accurate force is needed. |

|

|

Gap Type Wave Springs: Gap Type Wave Springs are usually installed in limited space, because of its non-deformation tendency and low medium coil force, they are more precise and reliable in performance in bearing Pre-loaded device. Pre tightening force of wave spring on bearing can attenuate noise and improve precision and stability during running of the bearing. |

|

|

Crest to Crest Wave Springs: These types of springs are pre stacked with round edge, flat wire in series, decreasing the spring rate proportionally to the number of turns. The springs are used in application requiring low-medium spring rates and large deflections with low- medium forces mainly used in ball valve, pressure relief valves, safety valves, clutches, auto clutch with bearing, gears and mechanical |

|

|

Chest to Chest Wave Springs: Flat Type wave springs except the character of Chest to Chest Wave Spring, provide entirely contact surface when compared to the wave point contact of plain ends. The flat end under load more evenly distributes the spring force upon adjacent components. The feature is similar to the concept of double disc grinding for a flat surface |

|

|

Overlap Type Wave Springs: Overlap Type Wave Springs are used in a wide variety of applications, for short deflections and low medium force; they function with precision and dependability. In the device of bear pre-load, this kind of springs can reduce running noise of bear and can also improves the accuracy and smoothness of bears. |

|

For further information and complete brochure on ITK Wave Springs including size details, standard material information, please contact ITK Sealing Solutions at This email address is being protected from spambots. You need JavaScript enabled to view it.